Qwik System Flush®

+ Accessories

QT1100 | QT1130 | QT1150

Absorbs 9x More Moisture Than Competitors

Removes 10x More Acid Than Competitors

A2L Compatible

Made on the Space Coast in Florida, USA

Qwik System Flush® + Accessories

Commonly known to technicians as “the orange can”, Qwik System Flush is our #1 Technician Recommended product when it comes to flushing out a line set. If there’s a burnout, change the compressor, refrigerant , oil , and flush the remaining components, with Qwik System Flush.

The Kit Includes:- Two 1-lb Aerosol Cans

- Charging Hose

- Can Access Valve

- QwikNozzle™

Qwik System Flush® is used to flush contaminants such as debris, residual oil, acid, and moisture from refrigeration line sets. If you can't replace refrigeration line sets after a burnout or a R-22 to R-410A change out, use Qwik System Flush to remove residual contamination. See our application bulletin for in-depth instructions on how to use Qwik System Flush.

Qwik System Flush® Packaging Options

- QT1100 – 2-lb aerosol can (services up to a 10-ton system)

- QT1130 – 1-lb aerosol can (services up to a 5-ton system)

- QT1150 – Complete starter kit includes:

- (2) 1-lb aerosol cans (QT1130)

- (1) Can access valve (QT1105)

- (1) QwikNozzle™ Line Set Flush Tool (QT1106)

- (1) Short charging hose

Equipment Needed to Flush a System Using Qwik System Flush®

The following equipment is required for each flushing operation:

-

- Qwik System Flush®. As a general rule, one 2-lb aerosol can cleans up to a 10-ton system. The amount you need will vary by size and level of contamination. See the chart below to estimate what you’ll need to complete your task.

| Part Number | Description |

| Qwik System Flush® | |

| QT1100 | 2-lb aerosol can for up to 10-ton systems |

| QT1130 | 1-lb aerosol can for up to 5-ton systems |

| QT1150 | (2) 1-lb aerosol cans for up to 10-ton systems |

- Qwik System Flush® Can Access Valve (QT1105 or supplied with QT1150 kit)

- Refrigerant charging hose with ¼" flare terminations (supplied with QT1150)

- A flare fitting for access to the section to be flushed – either a flare fitting that you can braze onto the piping, a line set flush tool (QT1110), or our QwikNozzle™ Squeeze-Handle Line Set Flush Tool (QT1106 or supplied with QT1150)

- An empty container to capture waste as it exits the line sets or components being flushed. Waste should be disposed of in accordance with local, state, and federal regulations.

- Compressed nitrogen cylinder with pressure regulator

- Safety glasses

- Protective gloves

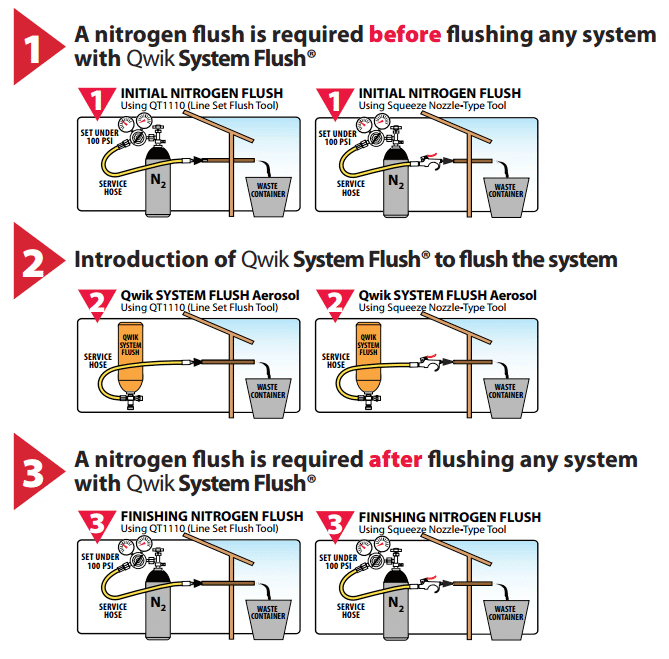

3 Steps to Flushing a System Using Qwik System Flush®

WARNING: Never connect Qwik System Flush® to a manifold set or to a nitrogen tank! The can will explode if pressurized!

Instructions for Using Qwik System Flush®

- Recover any refrigerant in the system.

- Open the system and cut out the following components:

- Filter-drier(s)

- Expansion valve(s)

- Compressor(s)

- Place a waste container where both nitrogen and flush-carrying waste will be exiting the system.

- Connect the nitrogen gas supply to a flare fitting and perform a nitrogen purge at each area you intend to flush. Let the nitrogen flow for at least 5 minutes or longer if debris continues to exit.

- The ideal use for the nitrogen is to physically blow as much contaminated oil out of the system that you can. Use your judgement to open the system anywhere you expect oil is trapped, and then use the nitrogen to blow this oil and other debris from the system. Never purge through an expansion device (capillary tube, orifice plate, TXV, etc.) this is likely to clog the device.

- Use Qwik System Flush to clean wherever you used nitrogen as a purge. If practical, the best method for cleaning piping or system components is to replace all the piping and system components. However, if full replacement is impractical, it must be cleaned by something more effective than nitrogen. A nitrogen purge is not capable of removing all the contaminated oil from the inside surface of a line set and should only be the beginning and end of a thorough cleaning process.

- After using nitrogen to purge the system, the most effective way to remove the remaining residual oil from the pipe lines is to use Mainstream’s Qwik System Flush. Remember, you must still perform a nitrogen purge before and after using Qwik-SF. The Qwik System Flush solvent has excellent absorption capacity, therefore, a relatively small amount of Qwik System Flush is needed. The more contamination you remove with a nitrogen purge before, the less Qwik System Flush will be wasted removing contamination that does not require a solvent. Nitrogen is much less expensive than any flushing solvent and should be used liberally in comparison.

- Repeat a nitrogen purge on all areas where Qwik System Flush was introduced into the line set. Never exceed 100 psig. When you purge these areas, the solvent exits the line as a liquid. Continue purging the line for an additional minute after you no longer see Qwik System Flush exiting the system.

- A flushing solvent cannot be used for components such as the compressor, filter-drier, or expansion device. Always remove filter–driers when performing a flush, and never try to flush through expansion devices.

- Connect the new components, installing BOTH a new liquid-line filter–drier and a new suction line filter–drier into the system. The purpose of the suction line drier is to catch residual acidic oil remaining in the system before it can enter the suction line of the compressor and contaminate the compressor oil, leading to premature compressor failure.

- Leak test, evacuate, and charge the system with refrigerant.

- As an option to further assure all acid and moisture has been removed, use QwikInjector to introduce QwikShot(refrigerant and oil treatment) into the operating system. One bottle treats up to a 6-ton system.

- Allow the system to operate for a minimum of 15 minutes, and then use QwikCheck to test for acid. If acid is detected, wait an additional 30 minutes and retest for acid. If acid is still detected, install new filter–driers again as discussed in step 10 and repeat steps 12–13.

FAQ

Have questions about Qwik System Flush?

- NuCalgon 4300-89

- NuCalgon 4300-99

If the cleaning product evaporates too fast then it does not have time to dissolve the oil and other impurities, it simply vaporizes and boils off without soaking into the liquid residue and without flushing the liquid waste out of the system. This is not good! Alternatively, we have specially engineered our patented Qwik System Flush® so that it does not evaporate too fast at atmospheric or higher pressures, so that it has time to soak into the oil and other impurities, dissolve them by diluting them, and flush them out of the system as a liquid waste.

Remember, the oil will never evaporate, and if the cleaning solution evaporates before it flushes the waste products out of the system, it will simply redeposit the waste products in another part of the system. Clearly not good! Instead, to properly clean and flush the system, the cleaning product must dissolve and mobilize the impurities, carry these solid and liquid waste products out of the system as a liquid waste stream. The minimal Qwik System Flush® residue that might remain in the system, is completely removed by the evacuation process, prior to refrigerant charging. Even a slight vacuum of only 2 - 3 inches of mercury vacuum would completely evaporate any residual Qwik System Flush®!

As you can see, the logic that you want a very fast evaporating cleaner is simply wrong. What is important is that the cleaner remain a liquid during flushing and then totally evaporates when evacuated. This is exactly what Mainstream's Qwik System Flush® does and is one reason why it flushes better than the other products tested.

Another point to consider is that all other flushes are simply degreasers, they are designed to remove oil, sludge and particulates. But what about the acid and moisture that remains on the metal surfaces? If acid and moisture are not removed, the fresh refrigerant charge will be contaminated with acid and water. Look at the independent, third party test results (performed by a testing lab and a university), we are much much better at removing acid and moisture, because Qwik System Flush® was specifically designed to remove acid and water in addition to sludge, oil and contaminates.

Qwik System Flush® is simply a better product at a better price. We have been shown to absorb water and acid as well as flush impurities, and this product is protected by US Patents #7,566,409 and #7,736,537.

Do not breathe any brand of chemical flushing agent, refrigerant vapors, industrial cleaners, or even high concentrations of nitrogen if you are pregnant.

Clearly the moisture absorbed from being exposed to air reduces the effectiveness of the remaining flush, and using a flushing agent that is saturated with moisture could actually add moisture to the system, rather than remove it! This is of course not a problem in the pressurized aerosol Qwik System Flush® can because the Qwik System Flush® is never exposed to air, except after the flushing process is completed.

In these cases, it is imperative that you flush the old line sets with Qwik System Flush® to remove the residual oil, acid, and moisture! Otherwise, these contaminants in the old lines will cause problems in the new system. Residual mineral oil and contaminates from the old system can contaminate the polyolester oil in the new R-410A system, forming a viscous sludge. Residual acid will continue to cause problems with a new system and moisture will accelerate the future formation of acid. Qwik System Flush® is the only flushing solution specially formulated to remove acid and water in addition to oil, sludge and contaminants.

In addition, if the oil line sets are located under the slab or in the walls of an air-conditioned house, where they can become cooler than the surrounding outdoor air, those tube runs can condense significant amounts of water, if these lines are left exposed to the air for any significant time during the change out. Never leave the line-sets open to the air and use Qwik System Flush® to get all the contaminates including acid and water out of these lines.

For more information on how to use Qwik System Flush® after a compressor burn out, see the Instructions link on the product page.