For a hermetic or semi-hermetic unit, checking for and removing acid is probably the most important maintenance check!

The operating life of refrigerators, heat pumps, and air conditioners are severely shortened by acid levels as low as 50 parts per million of acid! These acids can be formed by chemical reactions with components and/or materials of construction, lubricating oils, and/or impurities. The instability of the refrigerant, and thus the formation of acids is accelerated by elevated temperatures which could be the result of improper operation, such as a failed condenser fan, a clogged air flow path, or an improper refrigerant change-over. Acid formation can also be the result of oil and/or refrigerant incompatibilities, such as mineral oil/POE oil incompatibilities, refrigerant/gasket material incompatibility (Viton/R-134a), low thermal stability of the HFC refrigerant/oil mixtures, or extended operation off the design point.

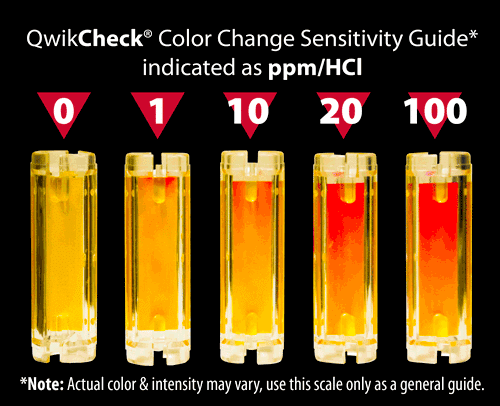

Checking the refrigerant and/or oil acid is a common maintenance recommendation since acidic conditions can be cleaned up before a compressor motor burns out. With the new HFC refrigerants, the various types of oils that could be in a system, and the recycling of refrigerant it is more important than ever to check the acid in a system. You can check for acid with any one of oil test kits on the market, I recommend the Mainstream QwikCheck® 2-second acid test because it is accurate, fast, and inexpensive. It will detect acid levels before they get to a harmful concentration, it works with all refrigerants and oils, and will not give a false reading when used with Ester-based oils. (The ability to be used with any oil is critical because you may not even accurately know the type of oil in a system!) Many oil acid test kits give a false acid reading with ester-based POE oils because the chemistry of the oil behaves like an acid to the test kit (The fancy name for this is Amphoteric properties).

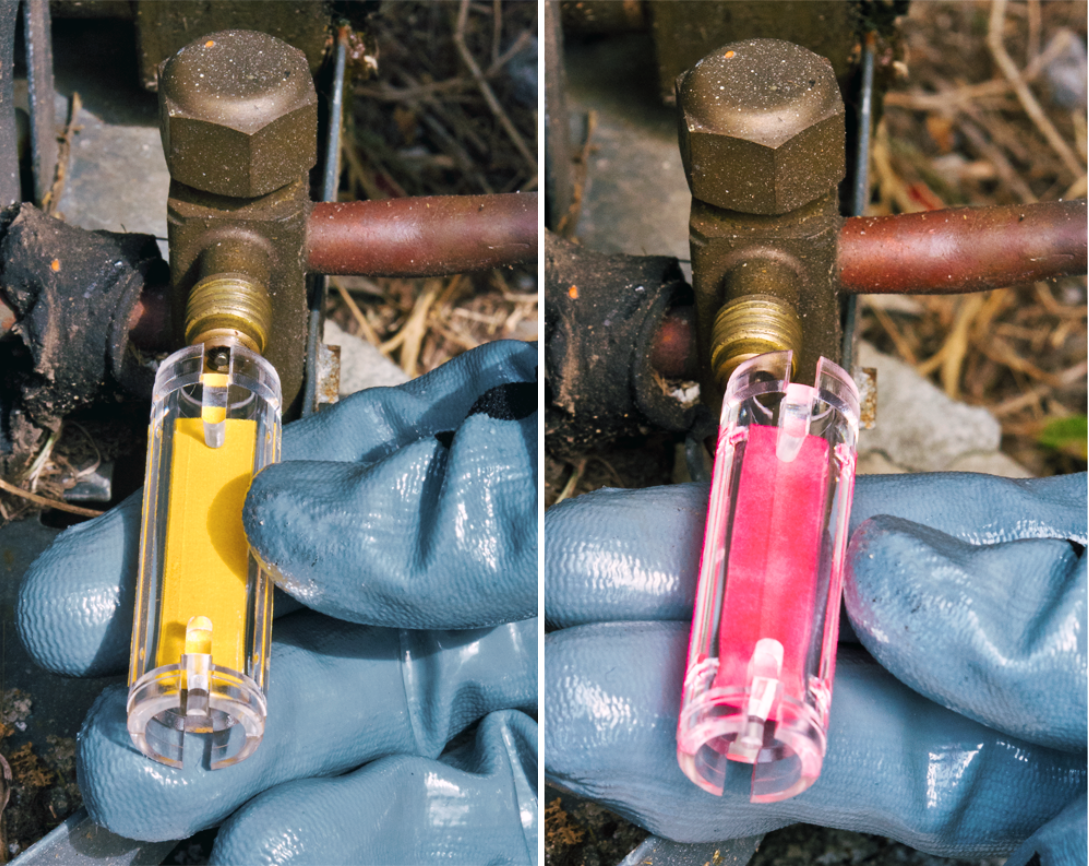

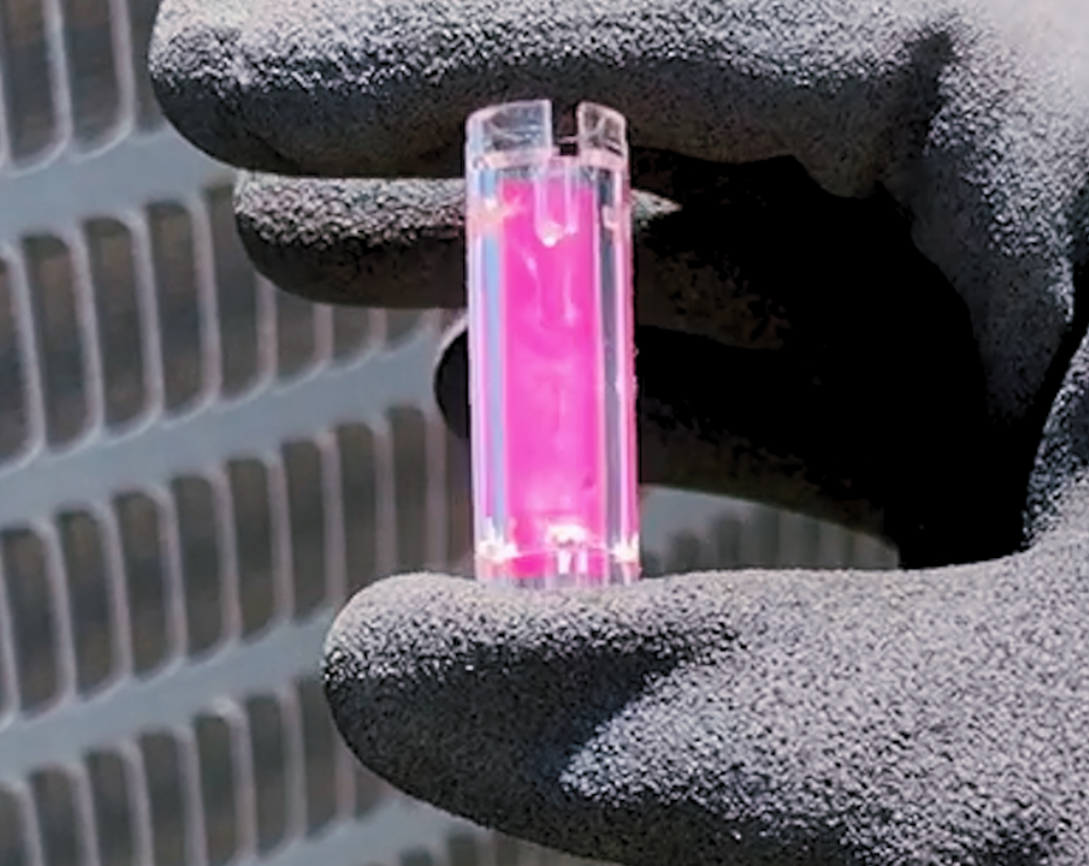

A really convenient thing about the QwikCheck®, is that for Hermetic Compressors it is very difficult to get some oil out for a oil acid test so what happens ... you probably never perform an acid test.... but these hermetic units are also the most sensitive to acid burn-outs! With QwikCheck®, you hold the QwikCheck® on the compressor service valve and 2-seconds later you have the results.

If acid is detected, use Mainstream's QwikShot® Refrigerant and Oil Treatment coupled with a filter/drier change to get rid of the acid BEFORE THIS ACID CAUSES THE SYSTEM TO BURN OUT.

QwikShot® is not just for burn-outs, it is also for preventative maintenance! For a few bucks and a few minutes of your time you have probably saved that compressor and that's the key to preventative maintenance.

The QwikShot® leaves no residue in the system, and it is compatible with all oils and refrigerants so it is quick, inexpensive, and easy to use. This patented Refrigerant and Oil Treatment is only available in the Mainstream QwikShot®. Another somewhat common BUT UNACCEPTABLE approach is to neutralizing this acid by reacting it with a base (the base which is typically a solid is dissolved in an alcohol solution) but this results in the formation of undesirable and corrosive salts and moisture in the system. While the filter dryer will remove the moisture, the corrosive salt is there forever!

Another serious problem with the acid-base neutralization approach is that the base is also a solid caustic compound, which if un-reacted in the system can cause as much damage as the acid itself and the proper quantity of base to add, to properly neutralize the acid, is difficult to determine in the field, since the exact acid level is probably not known.

Don't trade one problem, namely acid, for another problem, namely corrosive salts or a corrosive solid base residue!

![]()