QwikSwap®

X1, X3, V3

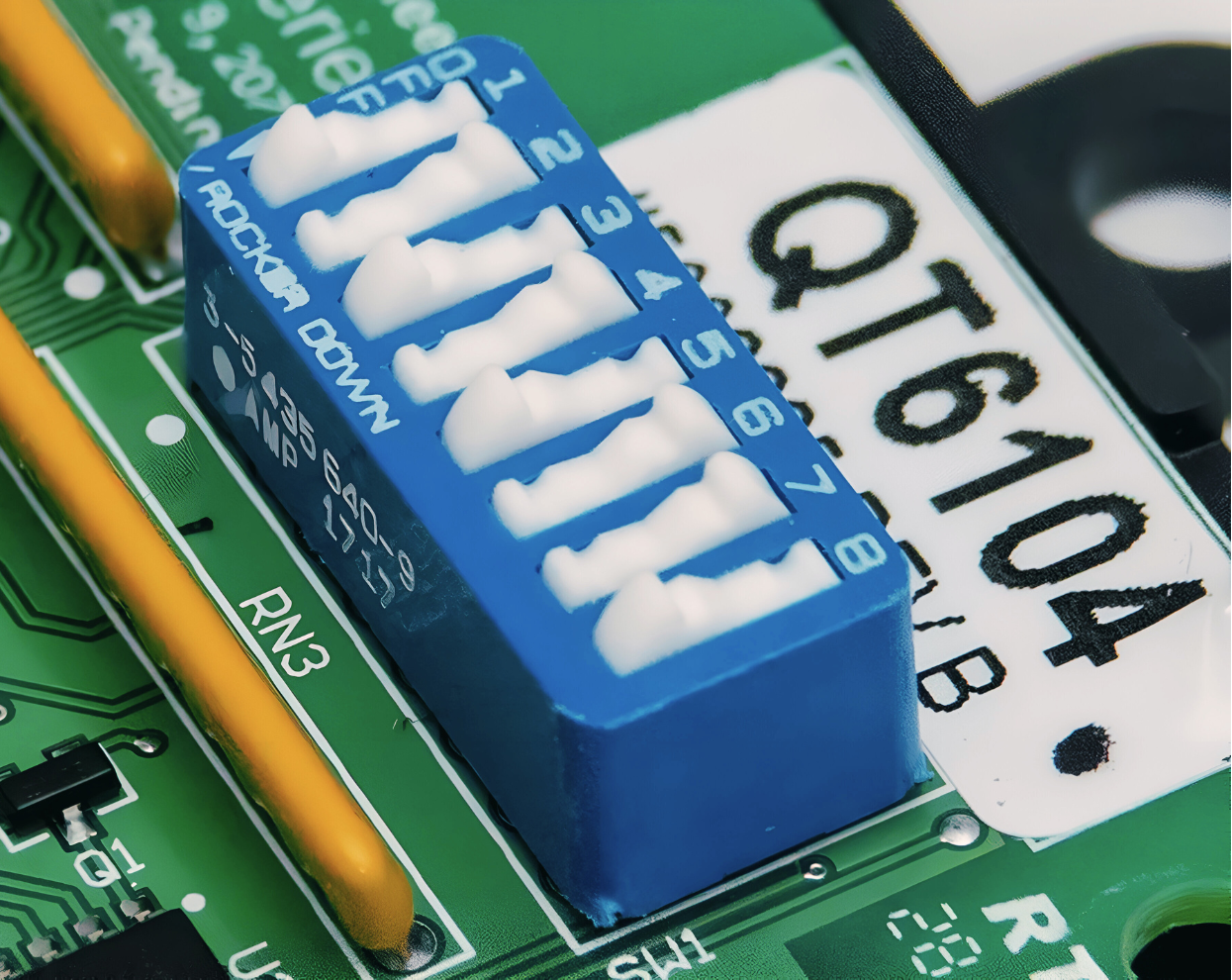

QT6101 | QT6100 | QT6104 | QT6110

Low-Cost Replacement

No Programming Necessary

1-Year Manufacturers Warranty

Made on the Space Coast in Florida, USA

QwikSwap® X1, X3, V3

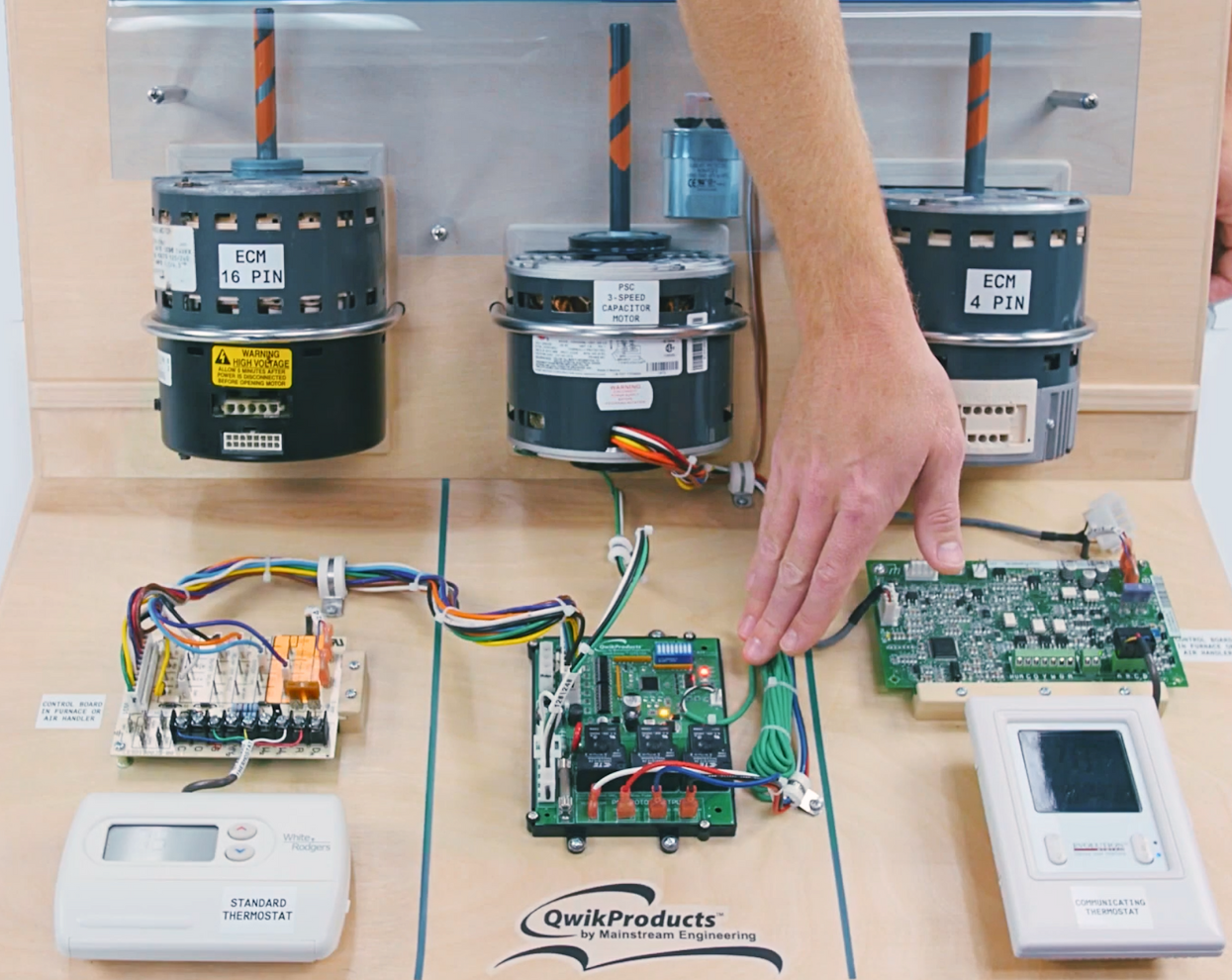

Direct replacement for any Constant Torque or Variable Air Flow ECM motor up to 1 HP. The solution is on your truck – No need to wait and pay for that expensive OEM motor replacement. Provides Variable Blower Air Flow (except the X1, QT6101)

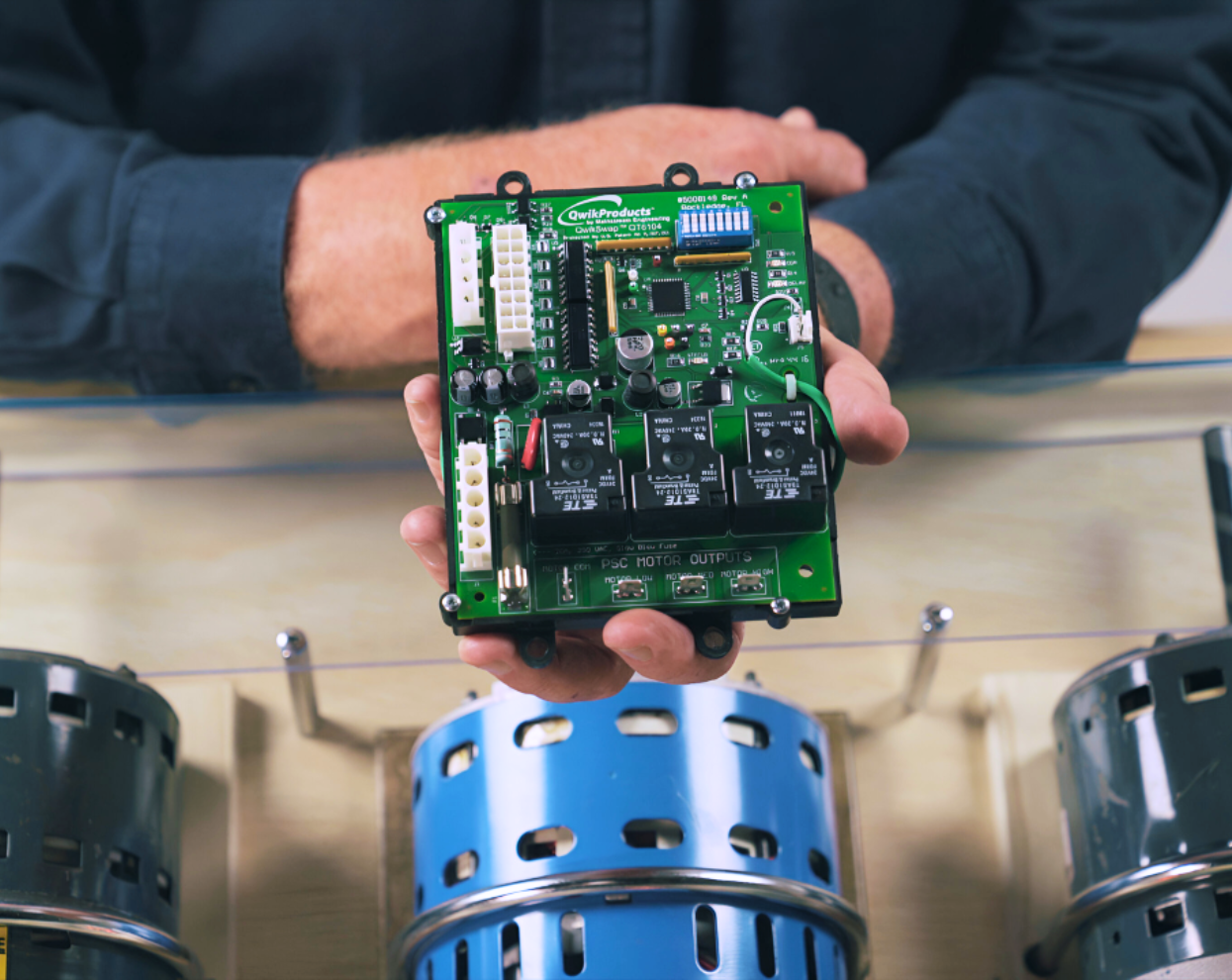

- Fast replacement without programming; simply transfer the connection from the ECM motor to the QwikSwap board and wire the QwikSwap board to any PSC motor

- The low-cost, robust alternative to expensive unreliable ECM motors

- Equipped with 6,000 Amp, 100 Joules surge protection on all high voltage circuits

- Patent-pending high efficiency designs

QwikSwap®

The ECM Motor Change-Out Solution... That’s On Your Truck!

- Direct replacement for any Constant Torque or Variable Air Flow ECM motor up to 1 HP

- The solution is on your truck – No need to wait and pay for that expensive OEM motor replacement

- Provides Variable Blower Air Flow (except the X1, QT6101)

- Fast Replacement, without programming; simply transfer the connection from the ECM motor to the QwikSwap Board and wire the QwikSwap board to any PSC motor

- Both the QwikSwap X3 and V3 automatically select the optimum PSC motor blower speed (Low, Medium or High) every time the unit cycles on

- Both the QwikSwap X3 and V3 provide improved humidity removal compared to fixed-speed operation (56 % improvement at 82°F, 157% at 97°F outdoor air temperature)

- Patent-pending high efficiency designs

- Equipped with 6,000 Amp, 100 Joules surge protection on all high voltage circuits

- Both the QwikSwap X3 and V3 work with optional Humidity Sensor (QT6001) for enhanced humidity removal

QwikSwap® The Low-Cost, Robust Alternative to Expensive Unreliable ECM Motors

It is impractical to have all the different variations of ECM motors on the truck, so a failed ECM blower motor typically means a trip to the parts house and a few hours wasted.

Now you can have the solution on the truck and save money too.

QwikSwap is a money saving solution that allows the replacement of a failed OEM ECM, X13® or SelecTech® Motor with a lower cost, more reliable, Permanent Split Capacitor (PSC) motor, along with a capacitor.

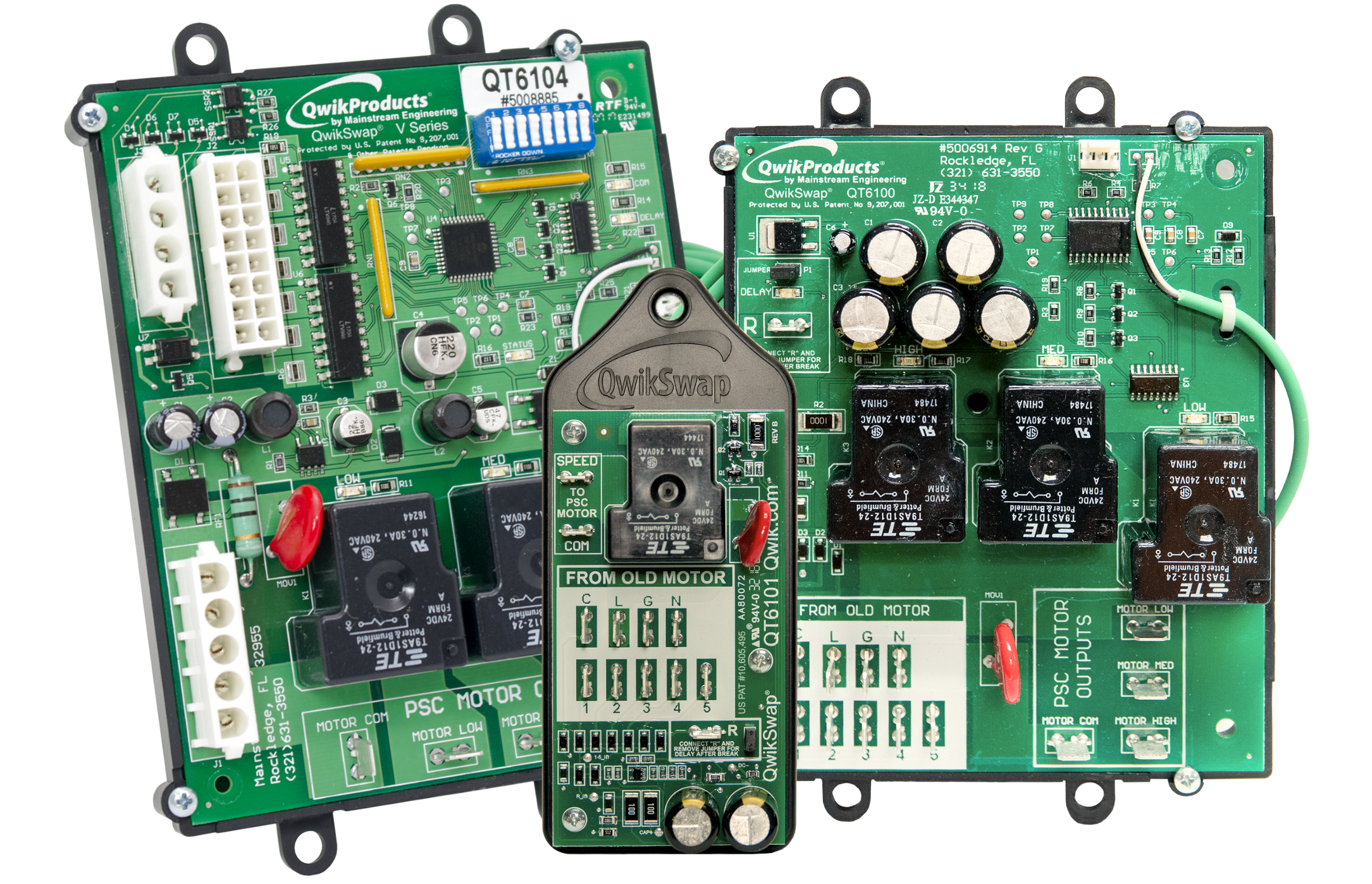

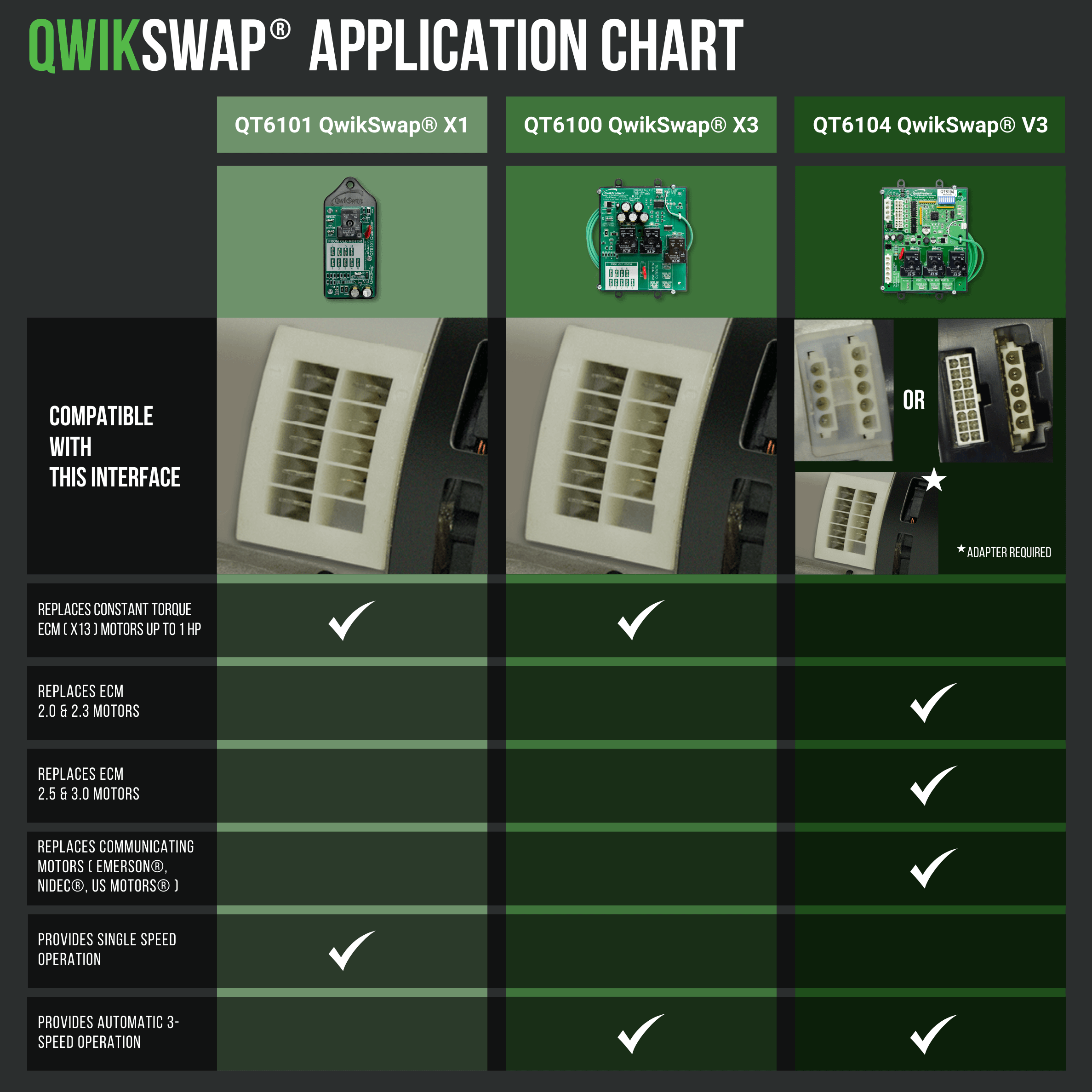

There is a QwikSwap board for every type of ECM motor...

and it is a solution you can have on the truck, with no custom programming required. QwikSwap boards operate with any PSC motor up to 1 horsepower, either 120 or 240 VAC single phase.

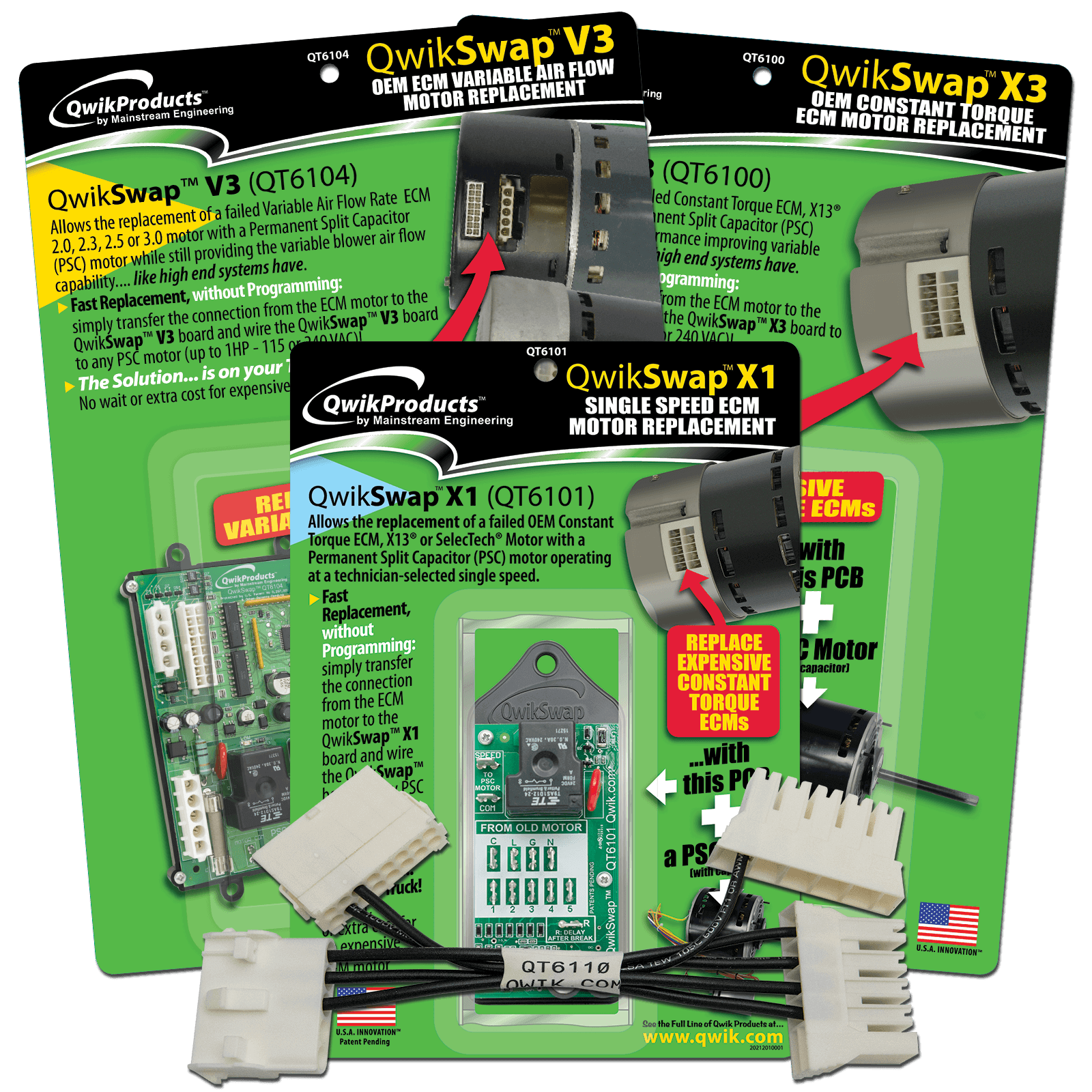

QwikSwap® X1 (QT6101)

The basic QwikSwap X1 (QT6101) provides a single technician-selected motor speed when replacing a failed OEM Constant Torque ECM, X13® or SelecTech® motor. Installation is as easy as moving wires from the failed ECM motor to the QwikSwap X1 board, then connecting the replacement PSC motor’s common and power lead to the QwikSwap X1 board (along with a capacitor).

QwikSwap® X3 (QT6100)

provides replacement of a failed OEM Constant Torque ECM, X13® or SelecTech® motor with Permanent Split Capacitor (PSC) motor while also ADDING performance improving variable blower air flow capability - like high end systems have. Installation is as simple as moving the wires from the failed ECM motor to the QwikSwap X3 board, then connecting the replacement PSC motor’s common and three power leads (one for each speed) to the QwikSwap X3 board (along with a capacitor).

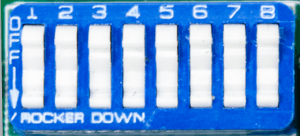

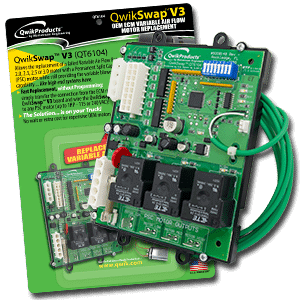

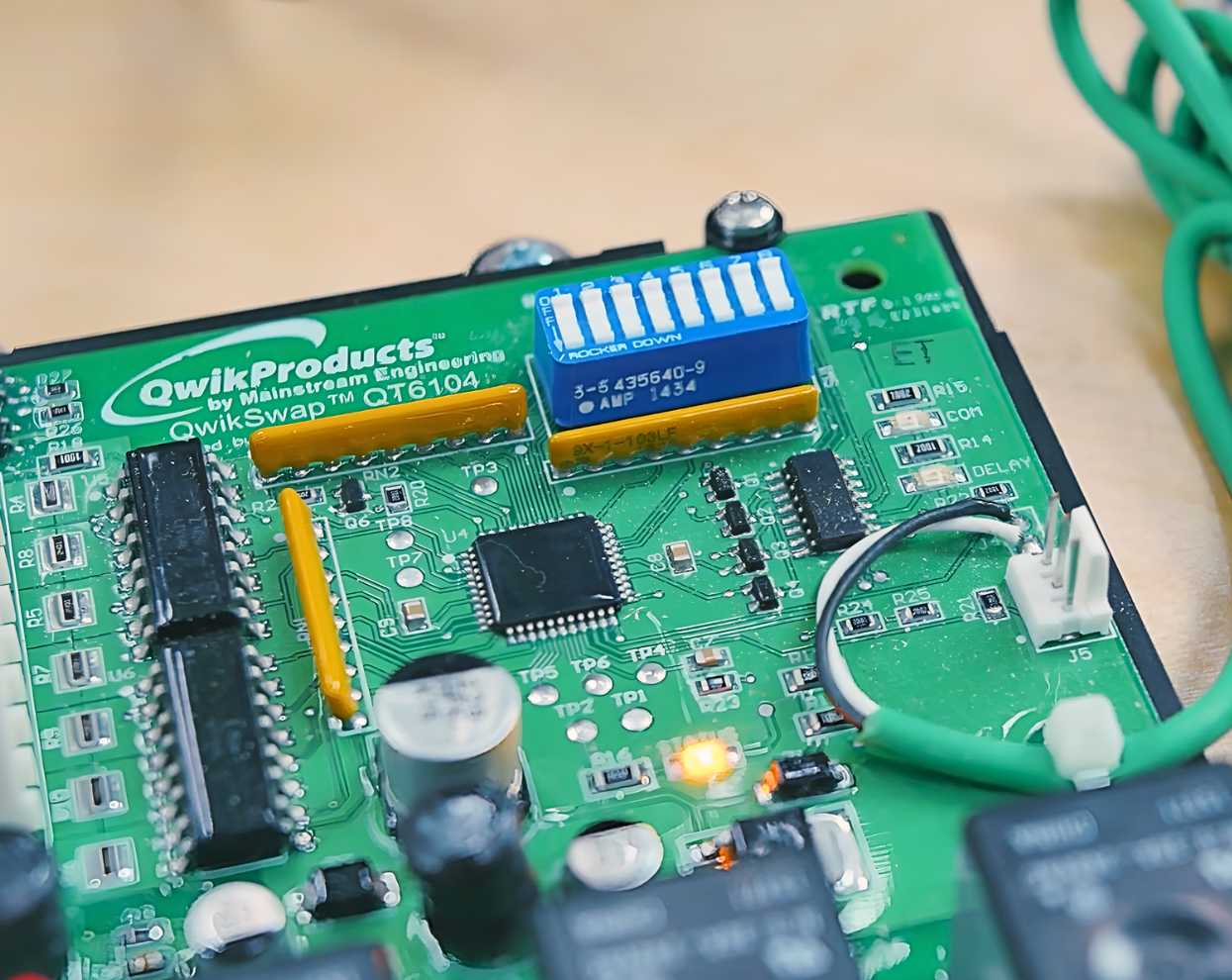

QwikSwap® V3 (QT6104)

provides replacement of a failed OEM Variable Air Flow Rate ECM 2.0. 2.3, 2.5 or 3.0 motor with a Permanent Split Capacitor (PSC) motor while maintaining variable blower air flow capability. As with any QwikSwap, installation simply requires moving wires from the failed ECM motor to the QwikSwap V3 board, then connecting the new PSC motor’s common and the three power leads (one for each speed) to the QwikSwap V3 board (along with a capacitor).

QwikConnect™ ECM Adapter (QT6110) Useful for replacing ECM 2.3 or Eon Motors in fan coil units to Evergreen® CM or EM motors. View the product data sheet and instructions for this adapter HERE.

Optional Humidity Sensor (QT6001)

While QwikSwap X3, QwikSwap V3 and our QwikSEER+ WattSaver all provide variable blower air flow leading to improved humidity removal, if humidly remains an issue these control boards have a simple plug-in connection for this optional humidly sensor. When installed on the control board and the relative humidity in the return air is measured to be greater than 50%, the control board control logic changes from maximizing performance to maximizing moisture removal. Once the humidity drops to below 50%, the control board returns to optimizing performance.

Specifications

QwikSwap™ X1

| Motor Voltage | 115 VAC or 208-240 VAC |

| Maximum Steady-State Current | 20 Amps |

| Maximum Blower Hp | 1 Hp |

| Delay After Break | 3 min (Option) |

| Frequency | 50 - 60 Hz |

| Surge Supression | 6,000 Amps, 100 Joules |

| Size / Dimensions | 2 3/8" x 5 1/2" |

QwikSwap™ X3

| Motor Voltage | 115 VAC or 240 VAC |

| Maximum Steady-State Current | 20 Amps |

| Maximum Blower Hp | 1 Hp |

| Delay After Break | 3 min (Option) |

| Frequency | 50 - 60 Hz |

| Surge Supression | 6,000 Amps, 100 Joules |

| Size / Dimensions | 4.3" x 5.3" |

| Supported Accessories | QT6001 Humidity Sensor |

QwikSwap™ V3

| Motor Voltage | 115 VAC or 240 VAC |

| Maximum Steady-State Current | 20 Amps |

| Maximum Blower Hp | 1 Hp |

| Delay After Break | 3 min (Option) |

| Frequency | 50 - 60 Hz |

| Surge Supression | 6,000 Amps, 100 Joules |

| Size / Dimensions | 4.3" x 5.3" |

| Supported Accessories | QT6001 Humidity Sensor |

FAQ

Have questions about QwikSwap?

Related Products