QwikShot®

Refrigerant & Oil Treatment

QT2501

Guaranteed Safe for All Systems

Leaves No Residue or Contamination

Removes Up To 26 Drops of Moisture

Made on the Space Coast in Florida, USA

QwikShot® Refrigerant & Oil Treatment

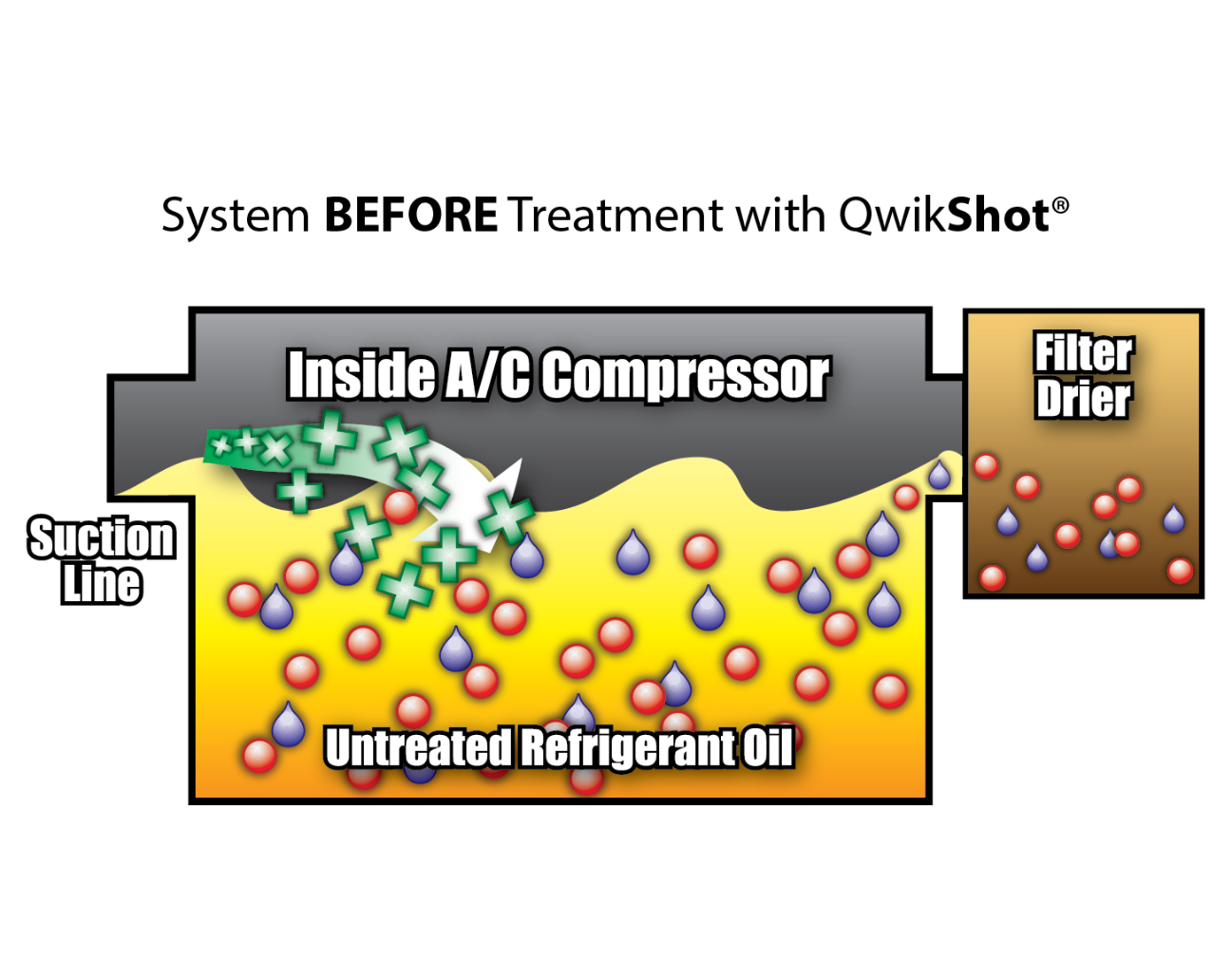

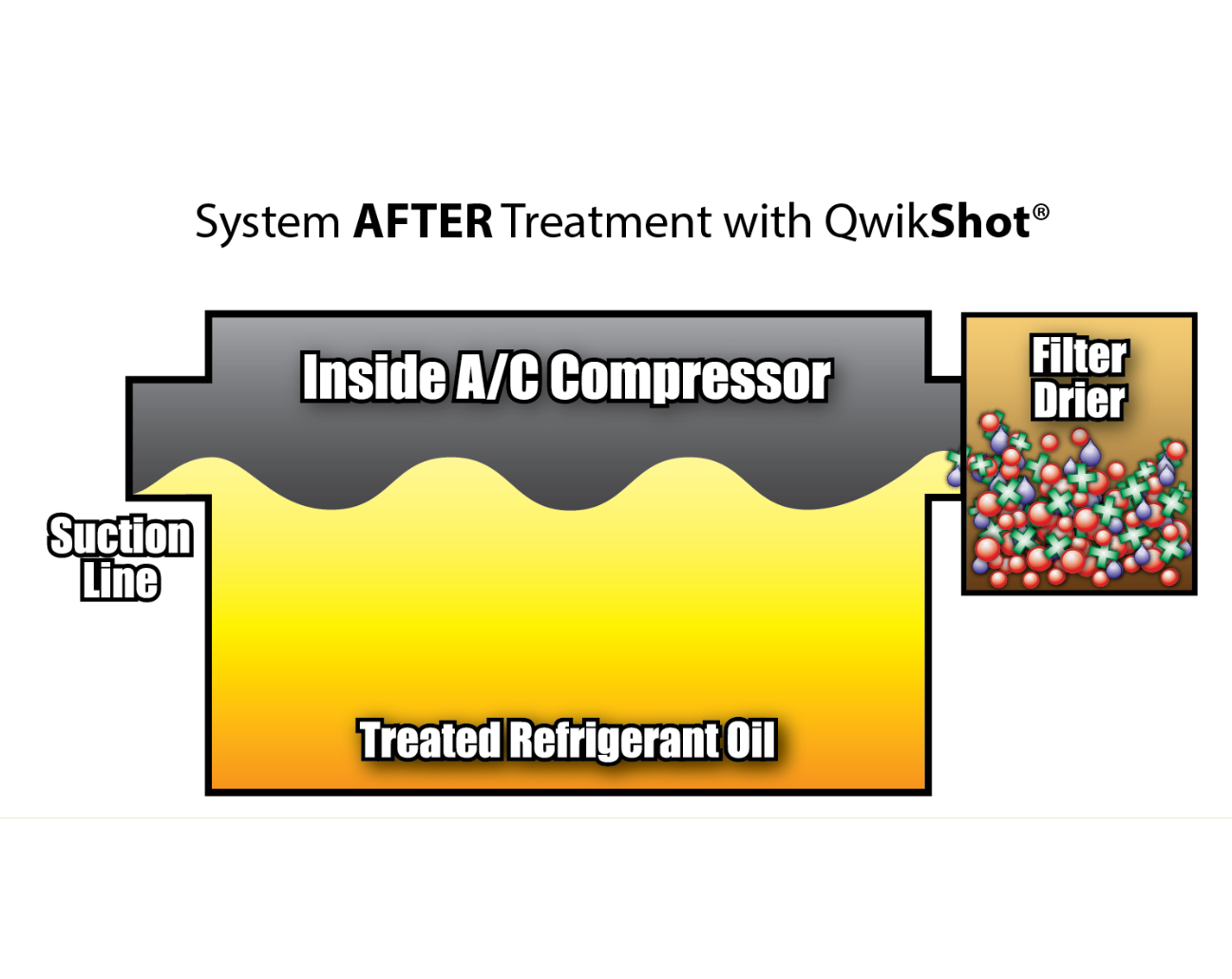

QwikShot Refrigerant and Oil Treatment has a unique formulation, which carries unwanted acid and moisture into the filter-drier where the acid, moisture and the QwikShot are removed. QwikShot is the only acid treatment on the market guaranteed not to invalidate any equipment manufacturer’s warranty!

- Easy Application

- Fast-Acting

- Compatible with All Refrigerants

- Non-Toxic and Non-Flammable

- Guaranteed safe for ALL systems

- OEM Approved

- Works with all refrigerants, oils, and filter-driers

- Produces no residue or contamination

- One bottle treats up to a 6-ton unit and removes up to 26 drops of moisture!

QwikShot Instructions for Use

For use with all refrigerants and oils used in air conditioning, heat pump, and refrigeration systems.Step 1 - Check the System and the Refrigerant for Acid If the compressor has burned out, change the compressor, refrigerant and oil. While the system is disassembled, flush acid from any components, (except the expansion device, filter-driers and compressor) with Qwik System Flush®. When reassembling the system, change the filter-driers (adding a suction-line filter is recommended to protect the new compressor). If the compressor has not burned out, and the system is operational, verify the system is properly charged and operating properly, verify superheat or subcooling as applicable, then use QwikCheck® to determine if the refrigerant is acidic

- If the refrigerant tests highly acidic (QwikCheck indicator turns all red), change the refrigerant and oil. Also, change the filter-driers since a high acid level indicates the current filter-driers are no longer functioning.

- If the refrigerant tests mildly acidic (some red on the QwikCheck), then measure the temperature across the liquid-line filter-drier (with the system on) to determine if a new drier is required. A temperature difference of more than 2°F indicates the filter-drier should be replaced. If there is no filter-drier in the system, you must add a filter-drier

- If the refrigerant does not test acidic (QwikCheck indicator stays yellow), go to step 2.

Step 3 - Add QwikShot using a QwikInjector® Add QwikShot into a charged and operating system by connecting the QwikInjector (QT2510) between the high and low-side service ports, connecting to the low side port first. Follow the QwikInjector instructions. Do not add QwikShot to a system before the system is evacuated (since the evacuation process will remove all the QwikShot).

Step 4 - After at Least 16 Hours of Operation, Check the System For highly acidic systems, after at least 16 hours of operation, you can recheck the system with a QwikCheck. If any sign of acid remains, repeat Steps 1-3.

FAQ

Have questions about QwikShot?

Excess QwikShot® Refrigerant and Oil Treatment does not hurt the system in any way, since it is also adsorbed into the filter drier. If there is no more acid to be removed from the system the QwikShot® Refrigerant and Oil Treatment will attract the excess water molecules next, and facilitate their transport into the drier. The QwikShot® Refrigerant and Oil Treatment does not in anyway affect the performance of the filter/drier. It does use some of the capacity of the drier, but since the drier is being changed this is not a problem. We do not even suggest using a larger drier, however, if desired you can use a 25% larger (by volume) drier if a molecular sieve drier is being replace and a 50% larger drier if an activated alumna drier is being replaced with another activated alumna drier. If an activated alumna drier is being replaced with a molecular sieve drier the capacity has already been increased substantially (by the improved adsorption capacity of the molecular sieve), and no increase in volume is recommended.

You must change the drier if there is a burn out. If you are going to do only one thing then change the drier. This must always be done on a burn out. Every compressor manufacturer specifies this and suggests you add a suction line drier to catch any residual acid in the lines (and keep this acid from reaching the compressor). We agree completely! So QwikShot Refrigerant and Oil Treatment should always be used with a new drier.

If you dont have a burn out, but you detect acid, you again must change the drier. Some acid neutralization companies, (but no compressor manufacturers) might tell you just neutralize the acid, you dont need to change the filter/drier WRONG. Ask any compressor manufacturer, they will all tell you that you must change the filter/drier!

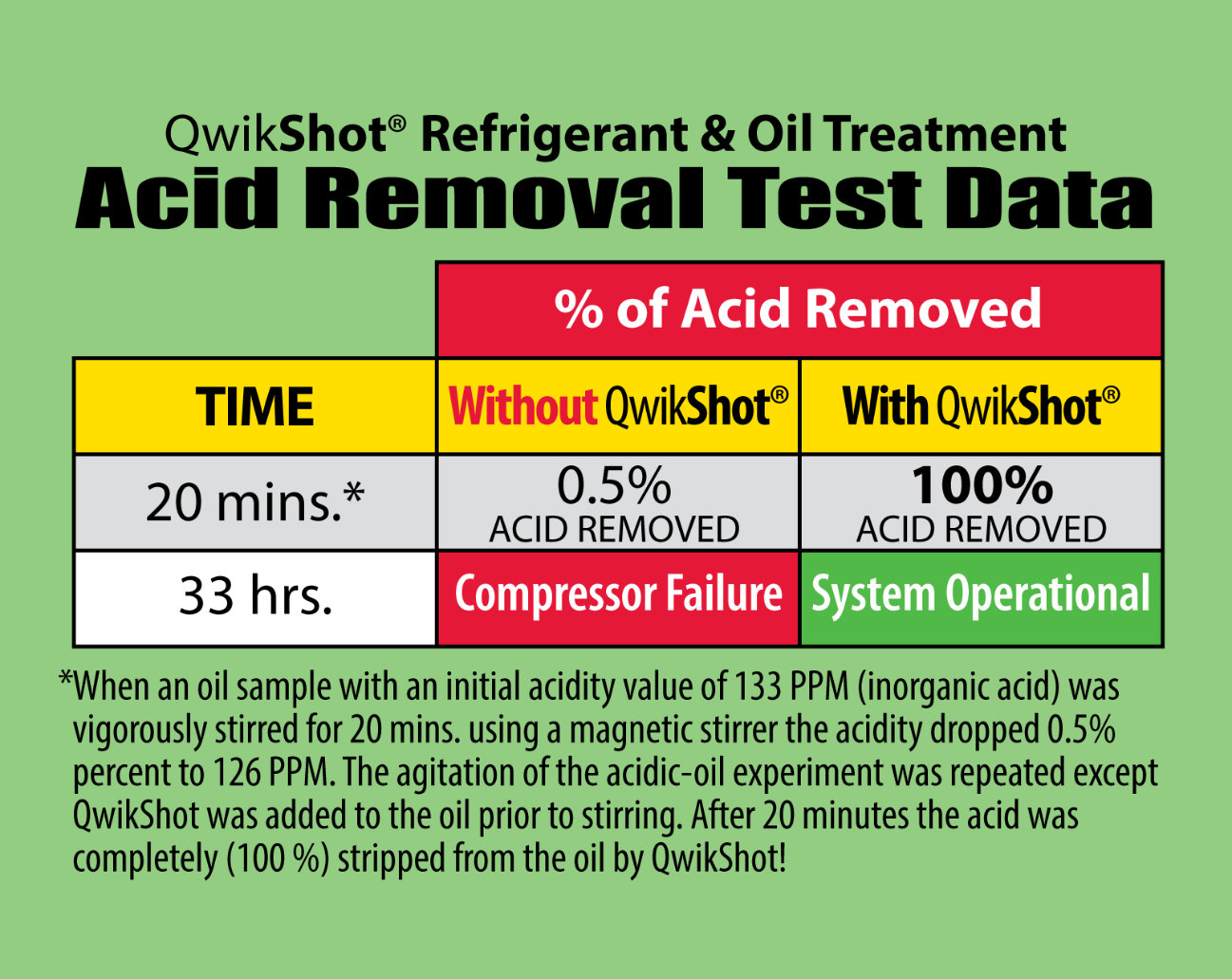

Again, if you do nothing else, change the drier, it is the most critical item! If you simply neutralize the acid that is present and dont change the drier, the acid and moisture levels can and will shoot right back up again, because you have left no back-up or residual protection. Neutralizing the acid only treats the system at the time it is added. Excess neutralizer reacts with the materials of construction (a potential problem) and is depleted (converted to a caustic salt); it does not remain active in the system to treat future acid. Only the drier remains in the system to remove acid and water as it appears. The problem with a high acid level is that the compressor will burn out, before the acid can be removed by the drier. QwikShot® Refrigerant and Oil Treatment accelerates the transport of acid to the drier, so that it can be removed faster.

Without a drier change, there is no capacity to maintain a low acid level. If you are not changing the drier, you are wasting your time, no matter what type of acid treatment you are using. Changing the filter/drier must always be performed, it is the most critical component of proper acid treatment!

The best way of removing the acid is to flush it or free it from the liquid and hard surfaces that contain the acid using QwikShot® Refrigerant and Oil Treatment, and let the filter-drier in the system remove the acid.

A filter-drier does an excellent job of removing acid, the problem is that normally the acid that is trapped on the hard surfaces and in the oil and therefore the acid never effectively gets to the filter-drier.

Another good, but very expensive approach to remove the acidic residue throughout the system is by performing several flushes of the vapor-compression system with refrigerant, since refrigerant will dissolve the oil and reduce the oil and acid concentrations by dilution. However, because of EPA mandated refrigerant recovery requirements, this is a costly and time consuming task and the cost of the refrigerant used in the flushing operation is not trivial.

The worst way is to attempt to neutralize the acid by reacting the acid with a basic solution (a solid base dissolved in a liquid carrier). This will always result in the formation of undesirable salts. In such a neutralization reaction, the acid and base combine to form a metallic caustic salt and water. While the water can be removed by the filter/dryer in the system, the salt remains lodged in the system and could cause problems. Since the salt is a solid it will not vaporize, but instead will remain in the compressor's crankcase. Also to properly neutralize the acid the proper amount of base must be added, too little base and the refrigerant is still acidic, too much base and the refrigerant is basic. An acidic or basic environment will cause corrosion and premature compressor life (burn-out).

The advantage to the patented QwikShot® Refrigerant and Oil Treatment approach of liberating the acid is that since there is no neutralization reaction there is no formation of a caustic salt residue. This innovative technology to provide this treatment action is patented and is only available in the QwikShot® Refrigerant and Oil Treatment. The other benefit of the use of QwikShot® is that not only is the acid picked up and removed from the system by the filter-drier, the QwikShot® is also picked-up and adsorbed by the filter-drier thereby leaving no residue at all in the system!

The QwikShot® Refrigerant and Oil Treatment is absorbed into the drier along with the acid or moisture, leaving no residue of any kind that could invalidate a warrantee. The QwikShot® will also accelerate the movement of moisture into the filter-drier. The QwikShot® Refrigerant and Oil Treatment dose uses only a fraction of the capacity of the filter-drier. If you are concerned, when you replace the filter-drier use a larger one (Approximately 25% larger if molecular sieve drier, 50% larger if an activated alumna drier).

Some people have suggested it is not necessary to change the filter-drier when acid is detected. This is completely wrong! Every compressor manufacturer recommends changing the filter-drier when acid is detected. It is a critical step, whether or not you use any acid treatment. The filter-drier must be changed or there is nothing in the system to stop future acid accumulation. The use of QwikShot® is the second step, since it accelerates the transport, of the acid in the system, into the filter-drier. This accelerated removal of acid is needed, because if acid is detected either: the filter-drier capacity is exhausted or the acid is being generated faster than the filter-drier can remove it. Our test results (see "A Discussion of Acid in Refrigeration Systems") have shown that once a significant amount of acid has been accumulated, if you only change the filter-drier, the acid level is so high it will most likely burn out the compressor before the filter-drier has a chance to get all the acid out. With QwikShot® Refrigerant and Oil Treatment, the transport of the acid is dramatically accelerated.

For a hermetic or semi-hermetic unit, checking for and removing acid is probably the most important maintenance check!

The operating life of refrigerators, heat pumps, and air conditioners are severely shortened by acid levels as low as 50 parts per million of acid! These acids can be formed by chemical reactions with components and/or materials of construction, lubricating oils, and/or impurities. The instability of the refrigerant, and thus the formation of acids is accelerated by elevated temperatures which could be the result of improper operation, such as a failed condenser fan, a clogged air flow path, or an improper refrigerant change-over. Acid formation can also be the result of oil and/or refrigerant incompatibilities, such as mineral oil/POE oil incompatibilities, refrigerant/gasket material incompatibility (Viton/R-134a), low thermal stability of the HFC refrigerant/oil mixtures, or extended operation off the design point.

Checking the refrigerant and/or oil acid is a common maintenance recommendation since acidic conditions can be cleaned up before a compressor motor burns out. With the new HFC refrigerants, the various types of oils that could be in a system, and the recycling of refrigerant it is more important than ever to check the acid in a system. You can check for acid with any one of oil test kits on the market, I recommend the Mainstream QwikCheck® 2-second acid test because it is accurate, fast, and inexpensive. It will detect acid levels before they get to a harmful concentration, it works with all refrigerants and oils, and will not give a false reading when used with Ester-based oils. (The ability to be used with any oil is critical because you may not even accurately know the type of oil in a system!) Many oil acid test kits give a false acid reading with ester-based POE oils because the chemistry of the oil behaves like an acid to the test kit (The fancy name for this is Amphoteric properties).

A really convenient thing about the QwikCheck®, is that for Hermetic Compressors it is very difficult to get some oil out for a oil acid test so what happens ... you probably never perform an acid test.... but these hermetic units are also the most sensitive to acid burn-outs! With QwikCheck®, you hold the QwikCheck® on the compressor service valve and 2-seconds later you have the results.

If acid is detected, use Mainstream's QwikShot® Refrigerant and Oil Treatment coupled with a filter/drier change to get rid of the acid BEFORE THIS ACID CAUSES THE SYSTEM TO BURN OUT.

QwikShot® is not just for burn-outs, it is also for preventative maintenance! For a few bucks and a few minutes of your time you have probably saved that compressor and that's the key to preventative maintenance.

The QwikShot® leaves no residue in the system, and it is compatible with all oils and refrigerants so it is quick, inexpensive, and easy to use. This patented Refrigerant and Oil Treatment is only available in the Mainstream QwikShot®. Another somewhat common BUT UNACCEPTABLE approach is to neutralizing this acid by reacting it with a base (the base which is typically a solid is dissolved in an alcohol solution) but this results in the formation of undesirable and corrosive salts and moisture in the system. While the filter dryer will remove the moisture, the corrosive salt is there forever!

Another serious problem with the acid-base neutralization approach is that the base is also a solid caustic compound, which if un-reacted in the system can cause as much damage as the acid itself and the proper quantity of base to add, to properly neutralize the acid, is difficult to determine in the field, since the exact acid level is probably not known.

Don't trade one problem, namely acid, for another problem, namely corrosive salts or a corrosive solid base residue!